Page 267 - Carmex - Inch Catalog 2018-19 Rev. B

P. 267

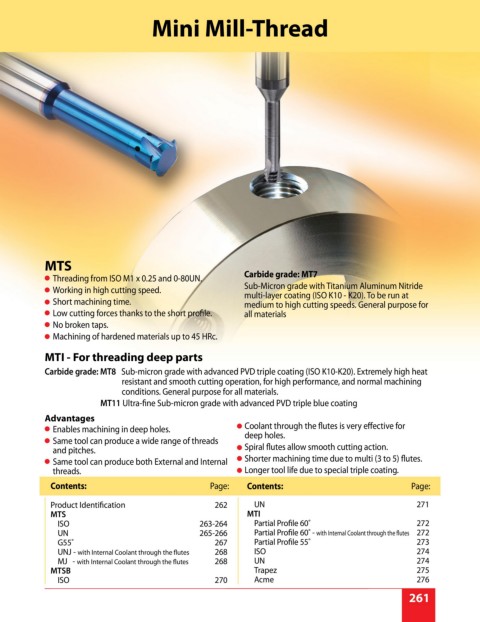

Mini Mill-Thread

MTS

Threading from ISO M1 x 0.25 and 0-80UN. Carbide grade: MT7

Working in high cutting speed. Sub-Micron grade with Titanium Aluminum Nitride

multi-layer coating (ISO K10 - K20). To be run at

Short machining time. medium to high cutting speeds. General purpose for

Low cutting forces thanks to the short profile. all materials

No broken taps.

Machining of hardened materials up to 45 HRc.

MTI - For threading deep parts

Carbide grade: MT8 Sub-micron grade with advanced PVD triple coating (ISO K10-K20). Extremely high heat

resistant and smooth cutting operation, for high performance, and normal machining

conditions. General purpose for all materials.

MT11 Ultra-fine Sub-micron grade with advanced PVD triple blue coating

Advantages

Enables machining in deep holes. Coolant through the flutes is very effective for

deep holes.

Same tool can produce a wide range of threads

Contents: Page:

and pitches. Spiral flutes allow smooth cutting action.

Same tool can produce both External and Internal Shorter machining time due to multi (3 to 5) flutes.

threads. Longer tool life due to special triple coating.

Contents: Page: Contents: Page:

Product Identification 262 UN 271

MTS MTI

ISO 263-264 Partial Profile 60˚ 272

UN 265-266 Partial Profile 60˚ - with Internal Coolant through the flutes 272

G55˚ 267 Partial Profile 55˚ 273

UNJ - with Internal Coolant through the flutes 268 ISO 274

MJ - with Internal Coolant through the flutes 268 UN 274

MTSB Trapez 275

ISO 270 Acme 276

5

261

127