Page 404 - Carmex - Metric Catalog 2021

P. 404

®

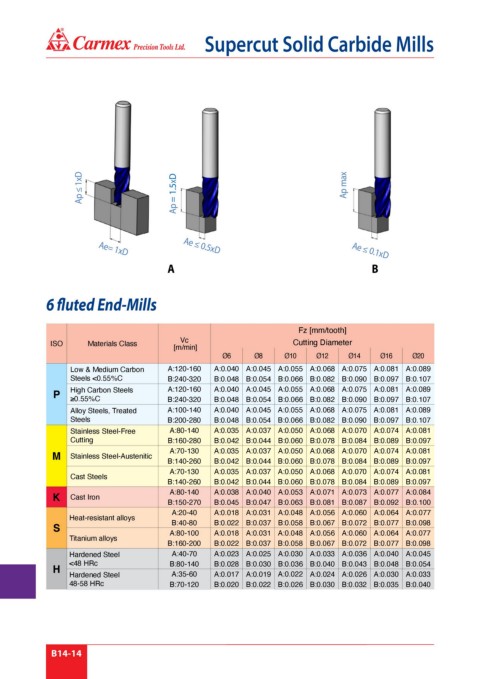

Supercut Solid Carbide Mills

Ap ≤ 1xD Ap = 1.5xD Ap max

Ae= 1xD Ae ≤ 0.5xD Ae ≤ 0.1xD

A B

6 fluted End-Mills

Fz [mm/tooth]

Vc

ISO Materials Class Cutting Diameter

[m/min]

Ø6 Ø8 Ø10 Ø12 Ø14 Ø16 Ø20

Low & Medium Carbon A:120-160 A:0.040 A:0.045 A:0.055 A:0.068 A:0.075 A:0.081 A:0.089

Steels <0.55%C B:240-320 B:0.048 B:0.054 B:0.066 B:0.082 B:0.090 B:0.097 B:0.107

High Carbon Steels A:120-160 A:0.040 A:0.045 A:0.055 A:0.068 A:0.075 A:0.081 A:0.089

P

≥0.55%C B:240-320 B:0.048 B:0.054 B:0.066 B:0.082 B:0.090 B:0.097 B:0.107

Alloy Steels, Treated A:100-140 A:0.040 A:0.045 A:0.055 A:0.068 A:0.075 A:0.081 A:0.089

Steels B:200-280 B:0.048 B:0.054 B:0.066 B:0.082 B:0.090 B:0.097 B:0.107

Stainless Steel-Free A:80-140 A:0.035 A:0.037 A:0.050 A:0.068 A:0.070 A:0.074 A:0.081

Cutting B:160-280 B:0.042 B:0.044 B:0.060 B:0.078 B:0.084 B:0.089 B:0.097

A:70-130 A:0.035 A:0.037 A:0.050 A:0.068 A:0.070 A:0.074 A:0.081

M Stainless Steel-Austenitic

B:140-260 B:0.042 B:0.044 B:0.060 B:0.078 B:0.084 B:0.089 B:0.097

A:70-130 A:0.035 A:0.037 A:0.050 A:0.068 A:0.070 A:0.074 A:0.081

Cast Steels

B:140-260 B:0.042 B:0.044 B:0.060 B:0.078 B:0.084 B:0.089 B:0.097

A:80-140 A:0.038 A:0.040 A:0.053 A:0.071 A:0.073 A:0.077 A:0.084

K Cast Iron

B:150-270 B:0.045 B:0.047 B:0.063 B:0.081 B:0.087 B:0.092 B:0.100

A:20-40 A:0.018 A:0.031 A:0.048 A:0.056 A:0.060 A:0.064 A:0.077

Heat-resistant alloys

B:40-80 B:0.022 B:0.037 B:0.058 B:0.067 B:0.072 B:0.077 B:0.098

S A:80-100 A:0.018 A:0.031 A:0.048 A:0.056 A:0.060 A:0.064 A:0.077

Titanium alloys

B:160-200 B:0.022 B:0.037 B:0.058 B:0.067 B:0.072 B:0.077 B:0.098

Hardened Steel A:40-70 A:0.023 A:0.025 A:0.030 A:0.033 A:0.036 A:0.040 A:0.045

<48 HRc B:80-140 B:0.028 B:0.030 B:0.036 B:0.040 B:0.043 B:0.048 B:0.054

H

Hardened Steel A:35-60 A:0.017 A:0.019 A:0.022 A:0.024 A:0.026 A:0.030 A:0.033

48-58 HRc B:70-120 B:0.020 B:0.022 B:0.026 B:0.030 B:0.032 B:0.035 B:0.040

B14-14