Page 172 - Carmex - Inch Catalog 2018-19 Rev. B

P. 172

®

Thread Whirling Tools

Thread Whirling Advantages

Thread Whirling offers several advantages over single point threading:

Enabling production of small diameter long threads when used on Swiss type machines, the thread

whirling spindle works close to the guide bushing for increased support and rigidity.

Increased Productivity:

Thread Whirling is performed in a single pass, resulting in a shorter machining time.

This eliminates multiple passes required for a single point threading.

Thread whirling allows working at high feed rates and consequently short cycle times.

Very high surface quality and accurate geometry:

The use of up to 8 cutting edges, higher concentricity, special cutting edge geometry and ideal chip

removal, enable top quality surfaces to be produced without burr.

Long tool life:

Whirling inserts have a stronger cutting edge than single point tools, because cutter side clearance is

achieved by rotating the whirling spindle, not by relieving material under the cutting edge.

Faster Setup:

Thread whirling eliminates special support devices and expensive startup development costs.

Compensation of large helix angles:

Large helix angles can be compensated by adjusting the whirling unit.

One toolholder can be used for various applications.

All toolholders are standard stock items.

Inserts are made for each application as a special item.

The toolholders are designed according to different machine types and manufacturers.

Special adaptors for machine heads are available as stock items.

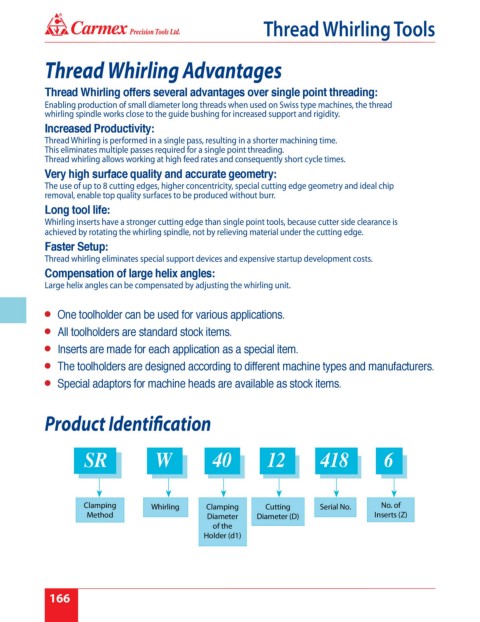

Product Identification

SR W 40 12 418 6

Clamping Whirling Clamping Cutting Serial No. No. of

Method Diameter Diameter (D) Inserts (Z)

of the

Holder (d1)

166