Page 177 - Carmex - Inch Catalog 2018-19 Rev. B

P. 177

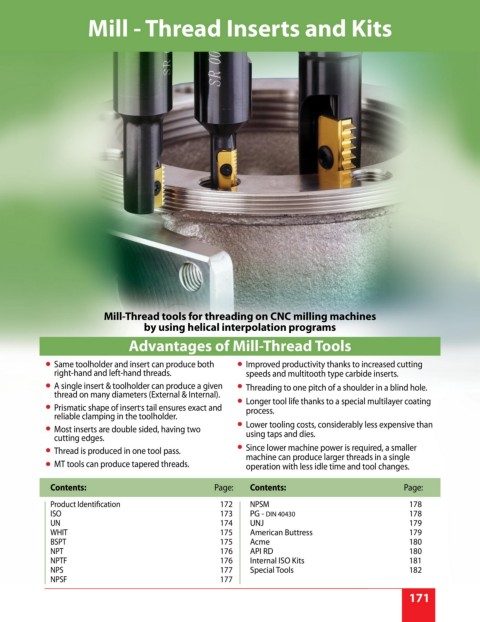

Mill - Thread Inserts and Kits

Mill-Thread tools for threading on CNC milling machines

by using helical interpolation programs

Advantages of Mill-Thread Tools

Same toolholder and insert can produce both Improved productivity thanks to increased cutting

right-hand and left-hand threads. speeds and multitooth type carbide inserts.

A single insert & toolholder can produce a given Threading to one pitch of a shoulder in a blind hole.

A combination of ground profile and sintered chip - breaker

thread on many diameters (External & Internal).

Prismatic shape of insert,s tail ensures exact and Longer tool life thanks to a special multilayer coating

process.

reliable clamping in the toolholder.

Most inserts are double sided, having two Lower tooling costs, considerably less expensive than

cutting edges. using taps and dies.

Thread is produced in one tool pass. Since lower machine power is required, a smaller

machine can produce larger threads in a single

MT tools can produce tapered threads. operation with less idle time and tool changes.

Contents: Page: Contents: Page:

Product Identification 172 NPSM 178

ISO 173 PG - DIN 40430 178

UN 174 UNJ 179

WHIT 175 American Buttress 179

BSPT 175 Acme 180

NPT 176 API RD 180

NPTF 176 Internal ISO Kits 181

NPS 177 Special Tools 182

NPSF 177

171