Page 32 - Carmex - X-treme Taps (Inch)

P. 32

®

Supercut Taps

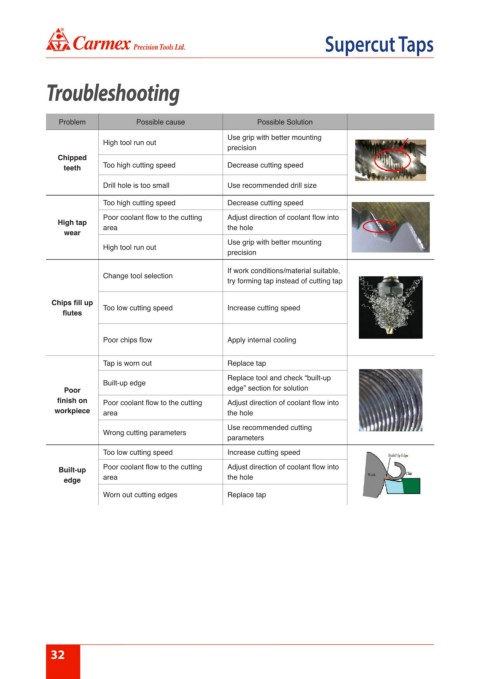

Troubleshooting

Problem Possible cause Possible Solution

Use grip with better mounting

High tool run out

precision

Chipped

Too high cutting speed Decrease cutting speed

teeth

Drill hole is too small Use recommended drill size

Too high cutting speed Decrease cutting speed

Poor coolant flow to the cutting Adjust direction of coolant flow into

High tap

area the hole

wear

Use grip with better mounting

High tool run out

precision

If work conditions/material suitable,

Change tool selection

try forming tap instead of cutting tap

Chips fill up

Too low cutting speed Increase cutting speed

flutes

Poor chips flow Apply internal cooling

Tap is worn out Replace tap

Replace tool and check “built-up

Built-up edge

Poor edge” section for solution

finish on Poor coolant flow to the cutting Adjust direction of coolant flow into

workpiece area the hole

Use recommended cutting

Wrong cutting parameters

parameters

Too low cutting speed Increase cutting speed

Built-up Poor coolant flow to the cutting Adjust direction of coolant flow into

edge area the hole

Worn out cutting edges Replace tap

32