Page 29 - Carmex - X-treme Taps (Inch)

P. 29

®

Supercut Taps

Forming Taps

Forming taps make thread by method of plastic deformation instead of cutting it. These taps are suitable for ductile

materials.

Rule of thumb is if the material produces continuous stringy chip it is probably a good candidate for thread forming.

Forming is ideal when absolutely chip free production is desired.

Note that the bore diameter required for formed thread is greater than bore diameter for cut thread.

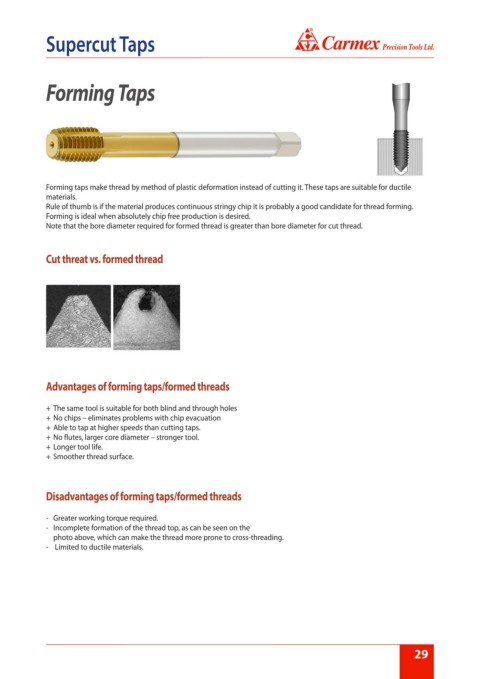

Cut threat vs. formed thread

Advantages of forming taps/formed threads

+ The same tool is suitable for both blind and through holes

+ No chips – eliminates problems with chip evacuation

+ Able to tap at higher speeds than cutting taps.

+ No flutes, larger core diameter – stronger tool.

+ Longer tool life.

+ Smoother thread surface.

Disadvantages of forming taps/formed threads

- Greater working torque required.

- Incomplete formation of the thread top, as can be seen on the

photo above, which can make the thread more prone to cross-threading.

- Limited to ductile materials.

29