Page 382 - Carmex - Metric Catalog 2021

P. 382

®

Mill-Thread Technical Section

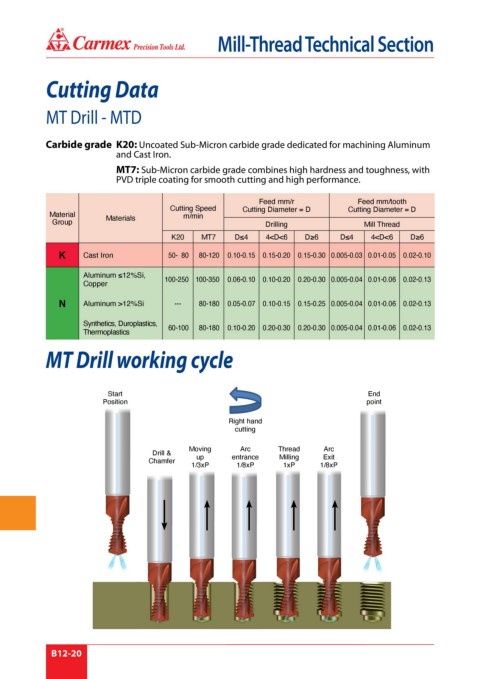

Cutting Data

MT Drill - MTD

Carbide grade K20: Uncoated Sub-Micron carbide grade dedicated for machining Aluminum

and Cast Iron.

MT7: Sub-Micron carbide grade combines high hardness and toughness, with

PVD triple coating for smooth cutting and high performance.

Feed mm/r Feed mm/tooth

Cutting Speed Cutting Diameter = D Cutting Diameter = D

Material Materials m/min

Group Drilling Mill Thread

K20 MT7 D≤4 4<D<6 D≥6 D≤4 4<D<6 D≥6

K Cast Iron 50- 80 80-120 0.10-0.15 0.15-0.20 0.15-0.30 0.005-0.03 0.01-0.05 0.02-0.10

Aluminum ≤12%Si, 100-250 100-350 0.06-0.10 0.10-0.20 0.20-0.30 0.005-0.04 0.01-0.06 0.02-0.13

Copper

N Aluminum >12%Si --- 80-180 0.05-0.07 0.10-0.15 0.15-0.25 0.005-0.04 0.01-0.06 0.02-0.13

Synthetics, Duroplastics, 60-100 80-180 0.10-0.20 0.20-0.30 0.20-0.30 0.005-0.04 0.01-0.06 0.02-0.13

Thermoplastics

MT Drill working cycle

Start End

Position point

Right hand

cutting

Moving Arc Thread Arc

Drill &

Chamfer up entrance Milling Exit

1/3xP 1/8xP 1xP 1/8xP

B12-20