Page 379 - Carmex - Metric Catalog 2021

P. 379

®

Mill-Thread Technical Section

Cutting Data

Mini Mill-Thread MTS, MTI and FMTI types

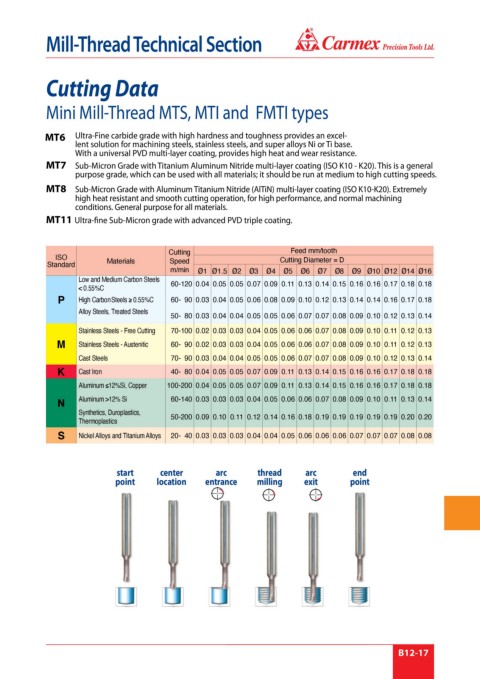

MT6

Ultra-Fine carbide grade with high hardness and toughness provides an excel-

lent solution for machining steels, stainless steels, and super alloys Ni or Ti base.

With a universal PVD multi-layer coating, provides high heat and wear resistance.

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20). This is a general

purpose grade, which can be used with all materials; it should be run at medium to high cutting speeds.

MT8 Sub-Micron Grade with Aluminum Titanium Nitride (AlTiN) multi-layer coating (ISO K10-K20). Extremely

high heat resistant and smooth cutting operation, for high performance, and normal machining

conditions. General purpose for all materials.

MT11 Ultra-fine Sub-Micron grade with advanced PVD triple coating.

Cutting Feed mm/tooth

ISO Materials Speed Cutting Diameter = D

Standard

m/min ø1 ø1.5 ø2 ø3 ø4 ø5 ø6 ø7 ø8 ø9 ø10 ø12 ø14 ø16

Low and Medium Carbon Steels

60-120 0.04 0.05 0.05 0.07 0.09 0.11 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.18

< 0.55%C

P High Carbon Steels ≥ 0.55%C 60- 90 0.03 0.04 0.05 0.06 0.08 0.09 0.10 0.12 0.13 0.14 0.14 0.16 0.17 0.18

Alloy Steels, Treated Steels

50- 80 0.03 0.04 0.04 0.05 0.05 0.06 0.07 0.07 0.08 0.09 0.10 0.12 0.13 0.14

Stainless Steels - Free Cutting 70-100 0.02 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

M Stainless Steels - Austenitic 60- 90 0.02 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13

Cast Steels 70- 90 0.03 0.04 0.04 0.05 0.05 0.06 0.07 0.07 0.08 0.09 0.10 0.12 0.13 0.14

K Cast Iron 40- 80 0.04 0.05 0.05 0.07 0.09 0.11 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.18

Aluminum ≤12%Si, Copper 100-200 0.04 0.05 0.05 0.07 0.09 0.11 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.18

N Aluminum >12% Si 60-140 0.03 0.03 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09 0.10 0.11 0.13 0.14

Synthetics, Duroplastics, 50-200 0.09 0.10 0.11 0.12 0.14 0.16 0.18 0.19 0.19 0.19 0.19 0.19 0.20 0.20

Thermoplastics

S Nickel Alloys and Titanium Alloys 20- 40 0.03 0.03 0.03 0.04 0.04 0.05 0.06 0.06 0.06 0.07 0.07 0.07 0.08 0.08

start center arc thread arc end

point location entrance milling exit point

B12-17