Page 425 - Carmex - Inch Catalog 2022

P. 425

®

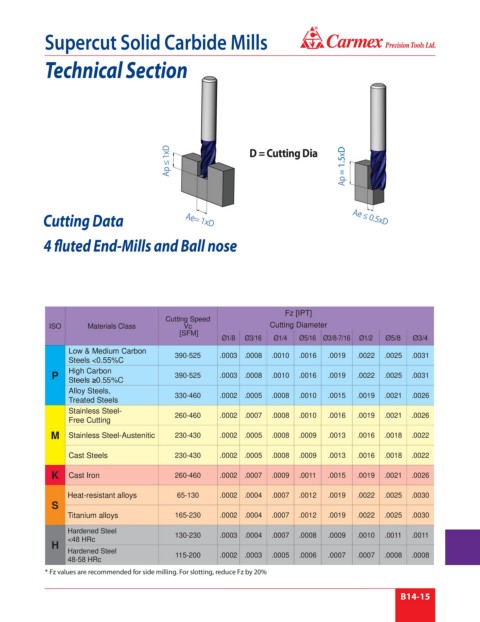

Supercut Solid Carbide Mills

Technical Section

Ap ≤ 1xD D = Cutting Dia Ap = 1.5xD

Cutting Data Ae= 1xD Ae ≤ 0.5xD

4 fluted End-Mills and Ball nose

Fz [IPT]

Cutting Speed

ISO Materials Class Vc Cutting Diameter

[SFM]

Ø1/8 Ø3/16 Ø1/4 Ø5/16 Ø3/8-7/16 Ø1/2 Ø5/8 Ø3/4

Low & Medium Carbon

390-525 .0003 .0008 .0010 .0016 .0019 .0022 .0025 .0031

Steels <0.55%C

High Carbon

P 390-525 .0003 .0008 .0010 .0016 .0019 .0022 .0025 .0031

Steels ≥0.55%C

Alloy Steels,

330-460 .0002 .0005 .0008 .0010 .0015 .0019 .0021 .0026

Treated Steels

Stainless Steel- 260-460 .0002 .0007 .0008 .0010 .0016 .0019 .0021 .0026

Free Cutting

M Stainless Steel-Austenitic 230-430 .0002 .0005 .0008 .0009 .0013 .0016 .0018 .0022

Cast Steels 230-430 .0002 .0005 .0008 .0009 .0013 .0016 .0018 .0022

K Cast Iron 260-460 .0002 .0007 .0009 .0011 .0015 .0019 .0021 .0026

Heat-resistant alloys 65-130 .0002 .0004 .0007 .0012 .0019 .0022 .0025 .0030

S

Titanium alloys 165-230 .0002 .0004 .0007 .0012 .0019 .0022 .0025 .0030

Hardened Steel 130-230 .0003 .0004 .0007 .0008 .0009 .0010 .0011 .0011

<48 HRc

H

Hardened Steel

115-200 .0002 .0003 .0005 .0006 .0007 .0007 .0008 .0008

48-58 HRc

* Fz values are recommended for side milling. For slotting, reduce Fz by 20%

Alternative

B14-15