Page 397 - Carmex - Inch Catalog 2022

P. 397

®

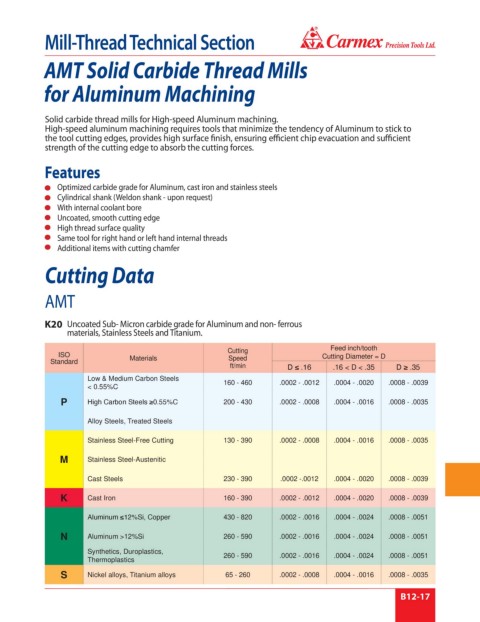

Mill-Thread Technical Section

AMT Solid Carbide Thread Mills

for Aluminum Machining

Solid carbide thread mills for High-speed Aluminum machining.

High-speed aluminum machining requires tools that minimize the tendency of Aluminum to stick to

the tool cutting edges, provides high surface finish, ensuring efficient chip evacuation and sufficient

strength of the cutting edge to absorb the cutting forces.

Features

Optimized carbide grade for Aluminum, cast iron and stainless steels

Cylindrical shank (Weldon shank - upon request)

With internal coolant bore

Uncoated, smooth cutting edge

High thread surface quality

Same tool for right hand or left hand internal threads

Additional items with cutting chamfer

Cutting Data

AMT

K20 Uncoated Sub- Micron carbide grade for Aluminum and non- ferrous

materials, Stainless Steels and Titanium.

Cutting Feed inch/tooth

ISO Cutting Diameter = D

Standard Materials Speed

ft/min D ≤ .16 .16 < D < .35 D ≥ .35

Low & Medium Carbon Steels 160 - 460 .0002 - .0012 .0004 - .0020 .0008 - .0039

< 0.55%C

P High Carbon Steels ≥0.55%C 200 - 430 .0002 - .0008 .0004 - .0016 .0008 - .0035

Alloy Steels, Treated Steels

Stainless Steel-Free Cutting 130 - 390 .0002 - .0008 .0004 - .0016 .0008 - .0035

M Stainless Steel-Austenitic

Cast Steels 230 - 390 .0002 -.0012 .0004 - .0020 .0008 - .0039

K Cast Iron 160 - 390 .0002 - .0012 .0004 - .0020 .0008 - .0039

Aluminum ≤12%Si, Copper 430 - 820 .0002 - .0016 .0004 - .0024 .0008 - .0051

N Aluminum >12%Si 260 - 590 .0002 - .0016 .0004 - .0024 .0008 - .0051

Synthetics, Duroplastics, 260 - 590 .0002 - .0016 .0004 - .0024 .0008 - .0051

Thermoplastics

S Nickel alloys, Titanium alloys 65 - 260 .0002 - .0008 .0004 - .0016 .0008 - .0035

B12-17