Page 394 - Carmex - Inch Catalog 2022

P. 394

®

Mill-Thread Technical Section

MTQ type

Thread mills with relieved neck and internal coolant for milling medium and large threads on

relatively deep work pieces.

Advantages

To produce medium and large threads on relatively Provides high rigidity and stability (anti-vibration).

deep work pieces. Accomplishes deep threads in one pass.

To use overhang according to the application. Relatively low cutting forces due to short cutting

To perform deep threads at the bottom of the length.

application. Threads length up to 3D.

Cutting Data

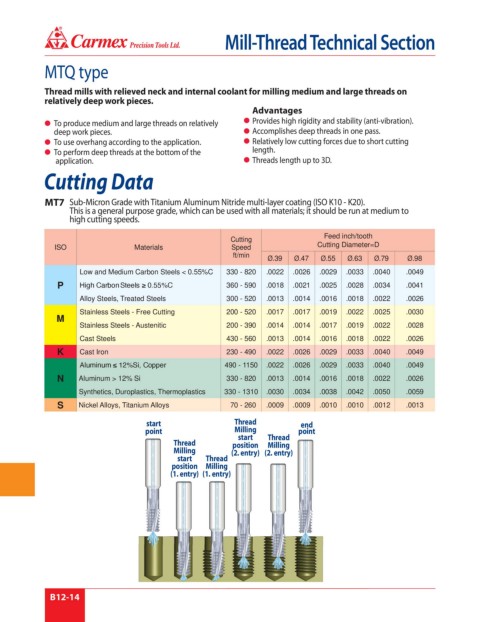

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20).

This is a general purpose grade, which can be used with all materials; it should be run at medium to

high cutting speeds.

Feed inch/tooth

Cutting

ISO Materials Speed Cutting Diameter=D

ft/min

Ø.39 Ø.47 Ø.55 Ø.63 Ø.79 Ø.98

Low and Medium Carbon Steels < 0.55%C 330 - 820 .0022 .0026 .0029 .0033 .0040 .0049

P High Carbon Steels ≥ 0.55%C 360 - 590 .0018 .0021 .0025 .0028 .0034 .0041

Alloy Steels, Treated Steels 300 - 520 .0013 .0014 .0016 .0018 .0022 .0026

Stainless Steels - Free Cutting 200 - 520 .0017 .0017 .0019 .0022 .0025 .0030

M

Stainless Steels - Austenitic 200 - 390 .0014 .0014 .0017 .0019 .0022 .0028

Cast Steels 430 - 560 .0013 .0014 .0016 .0018 .0022 .0026

K Cast Iron 230 - 490 .0022 .0026 .0029 .0033 .0040 .0049

Aluminum ≤ 12%Si, Copper 490 - 1150 .0022 .0026 .0029 .0033 .0040 .0049

N Aluminum > 12% Si 330 - 820 .0013 .0014 .0016 .0018 .0022 .0026

Synthetics, Duroplastics, Thermoplastics 330 - 1310 .0030 .0034 .0038 .0042 .0050 .0059

S Nickel Alloys, Titanium Alloys 70 - 260 .0009 .0009 .0010 .0010 .0012 .0013

start Thread end

point Milling point

start

Thread position Thread

Milling

Milling (2. entry) (2. entry)

start Thread

position Milling

(1. entry) (1. entry)

B12-14