Page 392 - Carmex - Inch Catalog 2022

P. 392

®

Mill-Thread Technical Section

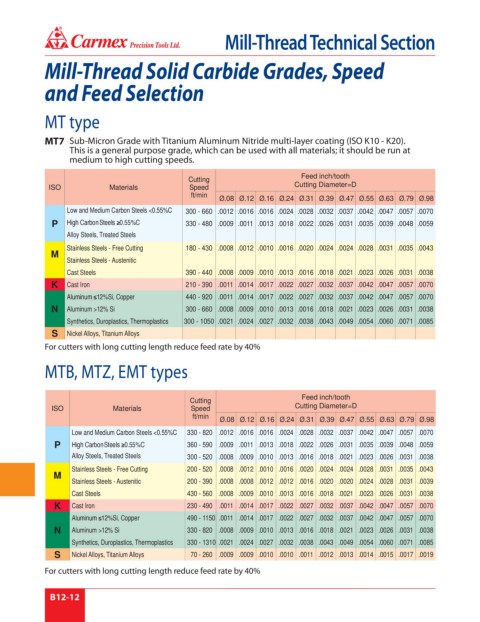

Mill-Thread Solid Carbide Grades, Speed

and Feed Selection

MT type

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20).

This is a general purpose grade, which can be used with all materials; it should be run at

medium to high cutting speeds.

Feed inch/tooth

Cutting

ISO Materials Speed Cutting Diameter=D

ft/min

Ø.08 Ø.12 Ø.16 Ø.24 Ø.31 Ø.39 Ø.47 Ø.55 Ø.63 Ø.79 Ø.98

Low and Medium Carbon Steels <0.55%C 300 - 660 .0012 .0016 .0016 .0024 .0028 .0032 .0037 .0042 .0047 .0057 .0070

P High Carbon Steels ≥0.55%C 330 - 480 .0009 .0011 .0013 .0018 .0022 .0026 .0031 .0035 .0039 .0048 .0059

Alloy Steels, Treated Steels

Stainless Steels - Free Cutting 180 - 430 .0008 .0012 .0010 .0016 .0020 .0024 .0024 .0028 .0031 .0035 .0043

M

Stainless Steels - Austenitic

Cast Steels 390 - 440 .0008 .0009 .0010 .0013 .0016 .0018 .0021 .0023 .0026 .0031 .0038

K Cast Iron 210 - 390 .0011 .0014 .0017 .0022 .0027 .0032 .0037 .0042 .0047 .0057 .0070

Aluminum ≤12%Si, Copper 440 - 920 .0011 .0014 .0017 .0022 .0027 .0032 .0037 .0042 .0047 .0057 .0070

N Aluminum >12% Si 300 - 660 .0008 .0009 .0010 .0013 .0016 .0018 .0021 .0023 .0026 .0031 .0038

Synthetics, Duroplastics, Thermoplastics 300 - 1050 .0021 .0024 .0027 .0032 .0038 .0043 .0049 .0054 .0060 .0071 .0085

S Nickel Alloys, Titanium Alloys

For cutters with long cutting length reduce feed rate by 40%

MTB, MTZ, EMT types

Feed inch/tooth

Cutting

ISO Materials Speed Cutting Diameter=D

ft/min

Ø.08 Ø.12 Ø.16 Ø.24 Ø.31 Ø.39 Ø.47 Ø.55 Ø.63 Ø.79 Ø.98

Low and Medium Carbon Steels <0.55%C 330 - 820 .0012 .0016 .0016 .0024 .0028 .0032 .0037 .0042 .0047 .0057 .0070

P High Carbon Steels ≥0.55%C 360 - 590 .0009 .0011 .0013 .0018 .0022 .0026 .0031 .0035 .0039 .0048 .0059

Alloy Steels, Treated Steels 300 - 520 .0008 .0009 .0010 .0013 .0016 .0018 .0021 .0023 .0026 .0031 .0038

Stainless Steels - Free Cutting 200 - 520 .0008 .0012 .0010 .0016 .0020 .0024 .0024 .0028 .0031 .0035 .0043

M

Stainless Steels - Austenitic 200 - 390 .0008 .0008 .0012 .0012 .0016 .0020 .0020 .0024 .0028 .0031 .0039

Cast Steels 430 - 560 .0008 .0009 .0010 .0013 .0016 .0018 .0021 .0023 .0026 .0031 .0038

K Cast Iron 230 - 490 .0011 .0014 .0017 .0022 .0027 .0032 .0037 .0042 .0047 .0057 .0070

Aluminum ≤12%Si, Copper 490 - 1150 .0011 .0014 .0017 .0022 .0027 .0032 .0037 .0042 .0047 .0057 .0070

N Aluminum >12% Si 330 - 820 .0008 .0009 .0010 .0013 .0016 .0018 .0021 .0023 .0026 .0031 .0038

Synthetics, Duroplastics, Thermoplastics 330 - 1310 .0021 .0024 .0027 .0032 .0038 .0043 .0049 .0054 .0060 .0071 .0085

S Nickel Alloys, Titanium Alloys 70 - 260 .0009 .0009 .0010 .0010 .0011 .0012 .0013 .0014 .0015 .0017 .0019

For cutters with long cutting length reduce feed rate by 40%

B12-12