Page 302 - Carmex - Inch Catalog 2018-19 Rev. B

P. 302

®

Mill - Thread Technical Section

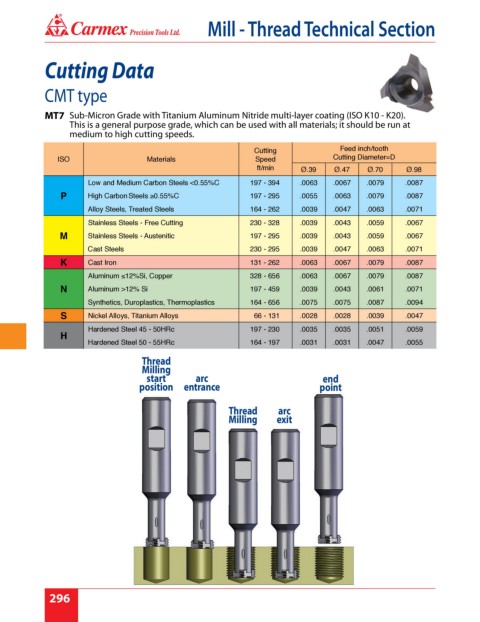

Cutting Data

CMT type

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20).

This is a general purpose grade, which can be used with all materials; it should be run at

medium to high cutting speeds.

Cutting Feed inch/tooth

ISO Materials Speed Cutting Diameter=D

ft/min Ø.39 Ø.47 Ø.70 Ø.98

Low and Medium Carbon Steels <0.55%C 197 - 394 .0063 .0067 .0079 .0087

P High Carbon Steels ≥0.55%C 197 - 295 .0055 .0063 .0079 .0087

Alloy Steels, Treated Steels 164 - 262 .0039 .0047 .0063 .0071

Stainless Steels - Free Cutting 230 - 328 .0039 .0043 .0059 .0067

M Stainless Steels - Austenitic 197 - 295 .0039 .0043 .0059 .0067

Cast Steels 230 - 295 .0039 .0047 .0063 .0071

K Cast Iron 131 - 262 .0063 .0067 .0079 .0087

Aluminum ≤12%Si, Copper 328 - 656 .0063 .0067 .0079 .0087

N Aluminum >12% Si 197 - 459 .0039 .0043 .0061 .0071

Synthetics, Duroplastics, Thermoplastics 164 - 656 .0075 .0075 .0087 .0094

S Nickel Alloys, Titanium Alloys 66 - 131 .0028 .0028 .0039 .0047

Hardened Steel 45 - 50HRc 197 - 230 .0035 .0035 .0051 .0059

H

Hardened Steel 50 - 55HRc 164 - 197 .0031 .0031 .0047 .0055

Thread

Milling

start arc end

position entrance point

Thread arc

Milling exit

8 296