Page 299 - Carmex - Inch Catalog 2018-19 Rev. B

P. 299

®

Mill - Thread Technical Section

M ill - T hr ead T echnical S ec tion

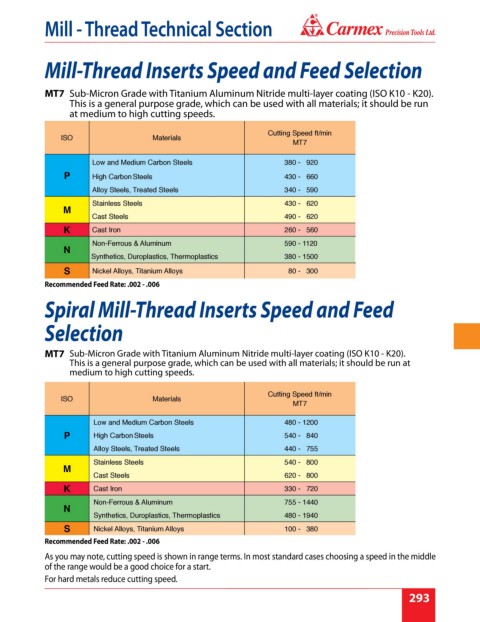

Mill-Thread Inserts Speed and Feed Selection

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20).

This is a general purpose grade, which can be used with all materials; it should be run

at medium to high cutting speeds.

Cutting Speed ft/min

ISO Materials

MT7

Low and Medium Carbon Steels 380 - 920

P High Carbon Steels 430 - 660

Alloy Steels, Treated Steels 340 - 590

Stainless Steels 430 - 620

M

Cast Steels 490 - 620

K Cast Iron 260 - 560

Non-Ferrous & Aluminum 590 - 1120

N

Synthetics, Duroplastics, Thermoplastics 380 - 1500

S Nickel Alloys, Titanium Alloys 80 - 300

Recommended Feed Rate: .002 - .006

Spiral Mill-Thread Inserts Speed and Feed

Selection

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20).

This is a general purpose grade, which can be used with all materials; it should be run at

medium to high cutting speeds.

Cutting Speed ft/min

ISO Materials

MT7

Low and Medium Carbon Steels 480 - 1200

P High Carbon Steels 540 - 840

Alloy Steels, Treated Steels 440 - 755

Stainless Steels 540 - 800

M

Cast Steels 620 - 800

K Cast Iron 330 - 720

Non-Ferrous & Aluminum 755 - 1440

N

Synthetics, Duroplastics, Thermoplastics 480 - 1940

S Nickel Alloys, Titanium Alloys 100 - 380

Recommended Feed Rate: .002 - .006

As you may note, cutting speed is shown in range terms. In most standard cases choosing a speed in the middle

of the range would be a good choice for a start.

For hard metals reduce cutting speed.

5

293