Page 54 - Carmex - Tiny Tools 2025 (Metric)

P. 54

®

Tiny Tools

CMR General Recommendations

Coolant fluid

Dry machining should not be performed under any circumstances.

It is necessary to use an internal coolant in all applications.

Oil or emulsion lubricants are recommended for best performance.

In the event of low coolant pressure, adding external coolant can improve tool operation.

The cooling stream is designed to provide three benefits:

1. Cooling the cutting edge of the tool and the contact area.

2. Pushing the chip away from the tool quickly, thereby reducing wear of the edge.

3. Helping to break the chip into smaller pieces and evacuating them from the cutting area.

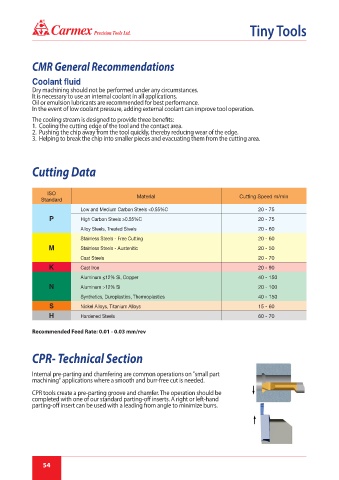

Cutting Data

ISO

Material Cutting Speed m/min

Standard

Low and Medium Carbon Steels <0.55%C 20 - 75

P High Carbon Steels ≥0.55%C 20 - 75

Alloy Steels, Treated Steels 20 - 60

Stainless Steels - Free Cutting 20 - 60

M Stainless Steels - Austenitic 20 - 50

Cast Steels 20 - 70

K Cast Iron 20 - 90

Aluminum ≤12% Si, Copper 40 - 150

N Aluminum >12% Si 20 - 100

Synthetics, Duroplastics, Thermoplastics 40 - 150

S Nickel Alloys, Titanium Alloys 15 - 60

H Hardened Steels 60 - 70

Recommended Feed Rate: 0.01 - 0.03 mm/rev

CPR- Technical Section

Internal pre-parting and chamfering are common operations on "small part

machining" applications where a smooth and burr-free cut is needed.

CPR tools create a pre-parting groove and chamfer. The operation should be

completed with one of our standard parting-off inserts. A right or left-hand

parting-off insert can be used with a leading from angle to minimize burrs.

54