Page 168 - Carmex - Metric Catalog 2021

P. 168

®

Mini Tools

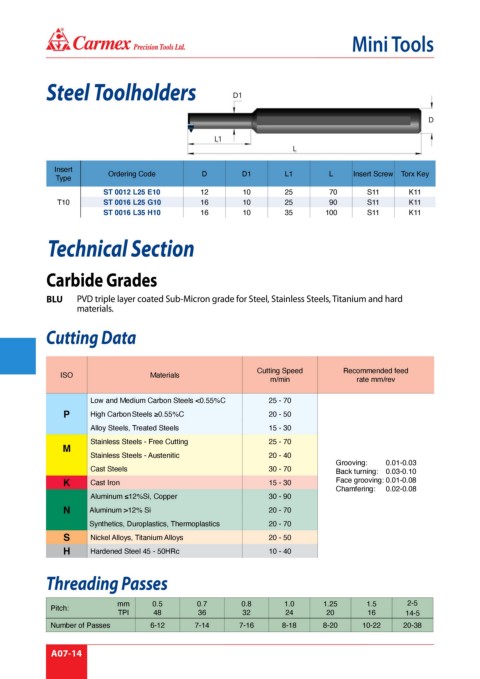

Steel Toolholders D1

D

L1

L

Insert Ordering Code D D1 L1 L Insert Screw Torx Key

Type

ST 0012 L25 E10 12 10 25 70 S11 K11

T10 ST 0016 L25 G10 16 10 25 90 S11 K11

ST 0016 L35 H10 16 10 35 100 S11 K11

Technical Section

Carbide Grades

BLU PVD triple layer coated Sub-Micron grade for Steel, Stainless Steels, Titanium and hard

materials.

Cutting Data

Cutting Speed Recommended feed

ISO Materials

m/min rate mm/rev

Low and Medium Carbon Steels <0.55%C 25 - 70

P High Carbon Steels ≥0.55%C 20 - 50

Alloy Steels, Treated Steels 15 - 30

Stainless Steels - Free Cutting 25 - 70

M

Stainless Steels - Austenitic 20 - 40

Grooving: 0.01-0.03

Cast Steels 30 - 70 Back turning: 0.03-0.10

K Cast Iron 15 - 30 Face grooving: 0.01-0.08

Chamfering: 0.02-0.08

Aluminum ≤12%Si, Copper 30 - 90

N Aluminum >12% Si 20 - 70

Synthetics, Duroplastics, Thermoplastics 20 - 70

S Nickel Alloys, Titanium Alloys 20 - 50

H Hardened Steel 45 - 50HRc 10 - 40

Threading Passes

mm 0.5 0.7 0.8 1.0 1.25 1.5 2-5

Pitch:

TPI 48 36 32 24 20 16 14-5

Number of Passes 6-12 7-14 7-16 8-18 8-20 10-22 20-38

A07-14