Page 324 - Carmex - Inch Catalog 2022

P. 324

®

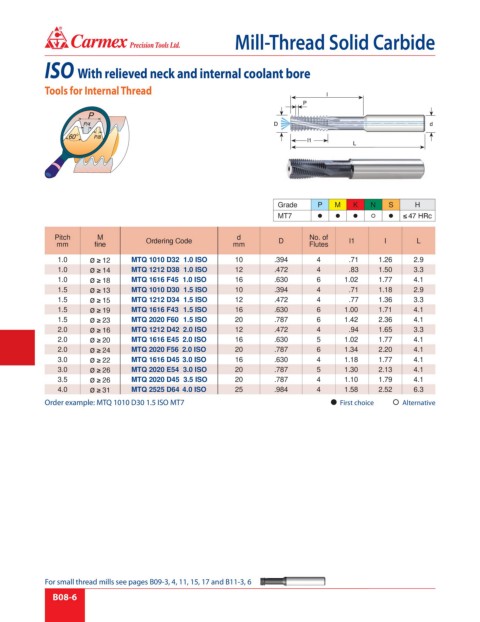

Mill-Thread Solid Carbide

ISO With relieved neck and internal coolant bore

Tools for Internal Thread

Grade P M K N S H

MT7 ≤ 47 HRc

Pitch M Ordering Code d D No. of l1 I L

mm fine mm Flutes

1.0 ø ≥ 12 MTQ 1010 D32 1.0 ISO 10 .394 4 .71 1.26 2.9

1.0 ø ≥ 14 MTQ 1212 D38 1.0 ISO 12 .472 4 .83 1.50 3.3

1.0 ø ≥ 18 MTQ 1616 F45 1.0 ISO 16 .630 6 1.02 1.77 4.1

1.5 ø ≥ 13 MTQ 1010 D30 1.5 ISO 10 .394 4 .71 1.18 2.9

1.5 ø ≥ 15 MTQ 1212 D34 1.5 ISO 12 .472 4 .77 1.36 3.3

1.5 ø ≥ 19 MTQ 1616 F43 1.5 ISO 16 .630 6 1.00 1.71 4.1

1.5 ø ≥ 23 MTQ 2020 F60 1.5 ISO 20 .787 6 1.42 2.36 4.1

2.0 ø ≥ 16 MTQ 1212 D42 2.0 ISO 12 .472 4 .94 1.65 3.3

2.0 ø ≥ 20 MTQ 1616 E45 2.0 ISO 16 .630 5 1.02 1.77 4.1

2.0 ø ≥ 24 MTQ 2020 F56 2.0 ISO 20 .787 6 1.34 2.20 4.1

3.0 ø ≥ 22 MTQ 1616 D45 3.0 ISO 16 .630 4 1.18 1.77 4.1

3.0 ø ≥ 26 MTQ 2020 E54 3.0 ISO 20 .787 5 1.30 2.13 4.1

3.5 ø ≥ 26 MTQ 2020 D45 3.5 ISO 20 .787 4 1.10 1.79 4.1

4.0 ø ≥ 31 MTQ 2525 D64 4.0 ISO 25 .984 4 1.58 2.52 6.3

Order example: MTQ 1010 D30 1.5 ISO MT7 First choice Alternative

To perform medium and large threads on

relatively deep work pieces.

To use overhang according to the application.

To perform deep threads at the bottom of the

application.

Advantages

Provides high rigidity and stability (anti-vibration).

Accomplishes deep threads in one pass.

Relatively low cutting forces due to short cutting

length.

Threads length up to 3D.

For small thread mills see pages B09-3, 4, 11, 15, 17 and B11-3, 6

B08-6