Page 78 - Carmex - Inch Catalog 2018-19 Rev. B

P. 78

®

Thread Turning Inserts Technical Section

Thread Turning - Step by Step

Step 1 : Choose Thread Turning Method

Step 2 : Choose Insert

Step 3 : Choose Toolholder

Step 4 : Choose Insert Grade

Step 5 : Choose Thread Turning Speed

Step 6 : Choose Number of Threading Passes

In most cases the above mentioned 6 steps would be the steps needed to ensure a good thread. When cutting more

complicated threads such as TRAPEZ, ACME, BUTTRESS or SAGE, it is advisable to check the effect of the thread

“HELIX ANGLE” on the “RESULTANT FLANK CLEARANCE” . If is smaller than 2°, an anvil change is required.

Step 7 : Find Thread Helix Angle

Step 8 : Choose Correct Anvil

EXAMPLES:

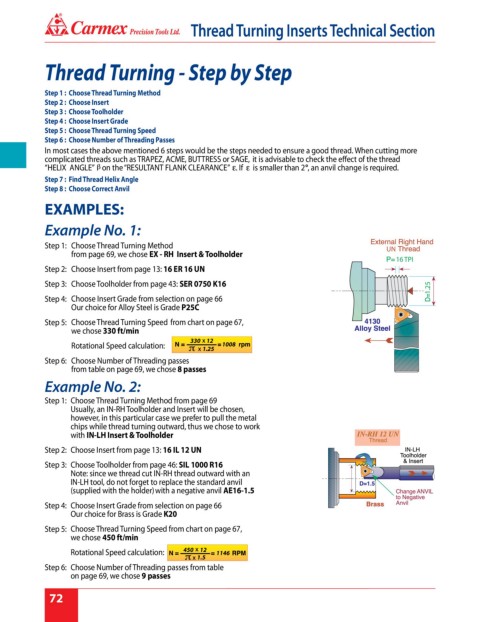

Example No. 1:

Step 1: Choose Thread Turning Method UN

from page 69, we chose EX - RH Insert & Toolholder

16 TPI

Step 2: Choose Insert from page 13: 16 ER 16 UN

Step 3: Choose Toolholder from page 43: SER 0750 K16 1.25

Step 4: Choose Insert Grade from selection on page 66

Our choice for Alloy Steel is Grade P25C

Step 5: Choose Thread Turning Speed from chart on page 67,

we chose 330 ft/min

Rotational Speed calculation: 330 12 1008

1.25

Step 6: Choose Number of Threading passes

from table on page 69, we chose 8 passes

Example No. 2:

Step 1: Choose Thread Turning Method from page 69

Usually, an IN-RH Toolholder and Insert will be chosen,

however, in this particular case we prefer to pull the metal

chips while thread turning outward, thus we chose to work

with IN-LH Insert & Toolholder

Step 2: Choose Insert from page 13: 16 IL 12 UN

Step 3: Choose Toolholder from page 46: SIL 1000 R16

Note: since we thread cut IN-RH thread outward with an

IN-LH tool, do not forget to replace the standard anvil

(supplied with the holder) with a negative anvil AE16-1.5

Step 4: Choose Insert Grade from selection on page 66

Our choice for Brass is Grade K20

Step 5: Choose Thread Turning Speed from chart on page 67,

we chose 450 ft/min

Rotational Speed calculation: 450 12 1146

1.5

Step 6: Choose Number of Threading passes from table

on page 69, we chose 9 passes

72