Page 73 - Carmex - Inch Catalog 2018-19 Rev. B

P. 73

®

Thread Turning Inserts Technical Section

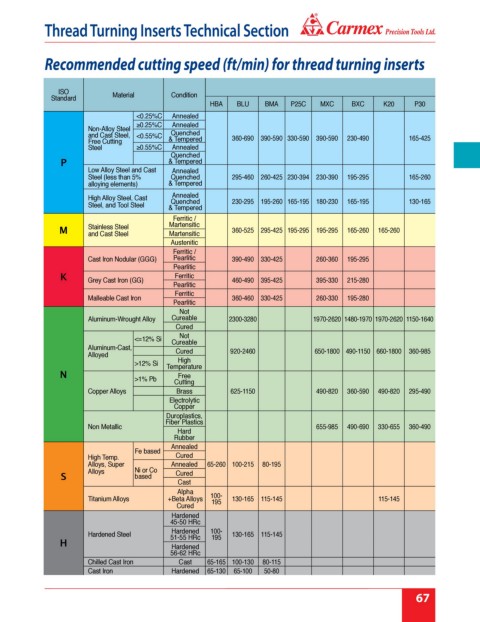

Recommended cutting speed (ft/min) for thread turning inserts

ISO

Standard Material Condition

HBA BLU BMA P25C MXC BXC K20 P30

<0.25%C Annealed

≥0.25%C Annealed

Non-Alloy Steel

and Cast Steel, <0.55%C Quenched 360-690 390-590 330-590 390-590 230-490 165-425

Free Cutting & Tempered

Steel ≥0.55%C Annealed

Quenched

P & Tempered

Low Alloy Steel and Cast Annealed

Steel (less than 5% Quenched 295-460 260-425 230-394 230-390 195-295 165-260

alloying elements) & Tempered

High Alloy Steel, Cast Annealed

Steel, and Tool Steel Quenched 230-295 195-260 165-195 180-230 165-195 130-165

& Tempered

Ferritic /

M Stainless Steel Martensitic 360-525 295-425 195-295 195-295 165-260 165-260

and Cast Steel

Martensitic

Austenitic

Ferritic /

Cast Iron Nodular (GGG) Pearlitic 390-490 330-425 260-360 195-295

Pearlitic

K Grey Cast Iron (GG) Ferritic 460-490 395-425 395-330 215-280

Pearlitic

Ferritic

Malleable Cast Iron 360-460 330-425 260-330 195-280

Pearlitic

Not

Aluminum-Wrought Alloy Cureable 2300-3280 1970-2620 1480-1970 1970-2620 1150-1640

Cured

Not

<=12% Si Cureable

Aluminum-Cast, Cured 920-2460 650-1800 490-1150 660-1800 360-985

Alloyed

High

>12% Si

Temperature

N Free

>1% Pb

Cutting

Copper Alloys Brass 625-1150 490-820 360-590 490-820 295-490

Electrolytic

Copper

Duroplastics,

Fiber Plastics

Non Metallic 655-985 490-690 330-655 360-490

Hard

Rubber

Annealed

Fe based

High Temp. Cured

Alloys, Super Annealed 65-260 100-215 80-195

Alloys Ni or Co Cured

S based

Cast

Alpha

Titanium Alloys +Beta Alloys 100- 130-165 115-145 115-145

195

Cured

Hardened

45-50 HRc

Hardened 100-

Hardened Steel 51-55 HRc 195 130-165 115-145

H Hardened

56-62 HRc

Chilled Cast Iron Cast 65-165 100-130 80-115

Cast Iron Hardened 65-130 65-100 50-80

67