Page 79 - Carmex - Inch Catalog 2018-19 Rev. B

P. 79

®

Thread Turning Inserts Technical Section

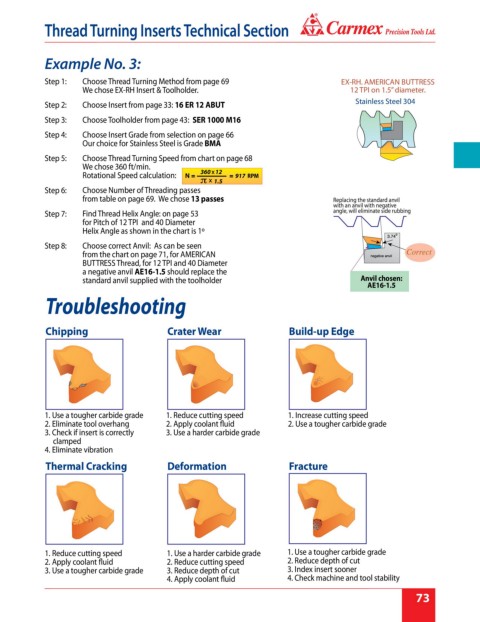

Example No. 3:

Step 1: Choose Thread Turning Method from page 69 EX-RH. AMERICAN BUTTRESS

We chose EX-RH Insert & Toolholder. 12 TPI on 1.5” diameter.

Stainless Steel 304

Step 2: Choose Insert from page 33: 16 ER 12 ABUT

Step 3: Choose Toolholder from page 43: SER 1000 M16

Step 4: Choose Insert Grade from selection on page 66

Our choice for Stainless Steel is Grade BMA

Step 5: Choose Thread Turning Speed from chart on page 68

We chose 360 ft/min.

Rotational Speed calculation: 360 12 917 RPM

1.5

Step 6: Choose Number of Threading passes

from table on page 69. We chose 13 passes Replacing the standard anvil

with an anvil with negative

Step 7: Find Thread Helix Angle: on page 53 angle, will eliminate side rubbing

for Pitch of 12 TPI and 40 Diameter

Helix Angle as shown in the chart is 1º

Step 8: Choose correct Anvil: As can be seen

from the chart on page 71, for AMERICAN

BUTTRESS Thread, for 12 TPI and 40 Diameter

a negative anvil AE16-1.5 should replace the

standard anvil supplied with the toolholder Anvil chosen:

AE16-1.5

Troubleshooting

Chipping Crater Wear Build-up Edge

1. Use a tougher carbide grade 1. Reduce cutting speed 1. Increase cutting speed

2. Eliminate tool overhang 2. Apply coolant fluid 2. Use a tougher carbide grade

3. Check if insert is correctly 3. Use a harder carbide grade

clamped

4. Eliminate vibration

Thermal Cracking Deformation Fracture

1. Reduce cutting speed 1. Use a harder carbide grade 1. Use a tougher carbide grade

2. Apply coolant fluid 2. Reduce cutting speed 2. Reduce depth of cut

3. Use a tougher carbide grade 3. Reduce depth of cut 3. Index insert sooner

4. Apply coolant fluid 4. Check machine and tool stability

73