Page 310 - Carmex - Inch Catalog 2018-19 Rev. B

P. 310

®

Mill - Thread Technical Section

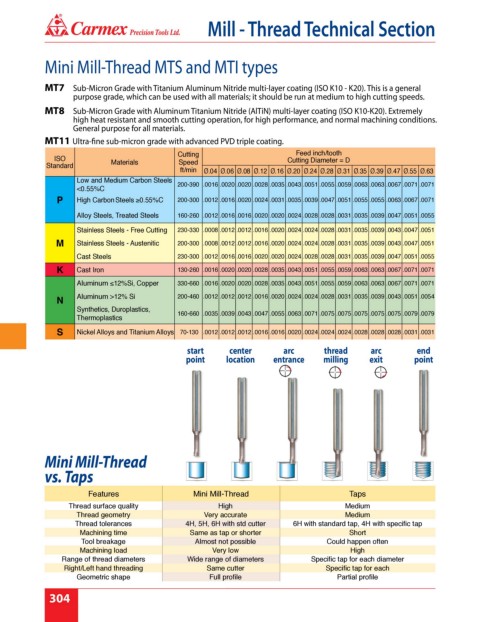

Mini Mill-Thread MTS and MTI types

MT7 Sub-Micron Grade with Titanium Aluminum Nitride multi-layer coating (ISO K10 - K20). This is a general

purpose grade, which can be used with all materials; it should be run at medium to high cutting speeds.

MT8 Sub-Micron Grade with Aluminum Titanium Nitride (AlTiN) multi-layer coating (ISO K10-K20). Extremely

high heat resistant and smooth cutting operation, for high performance, and normal machining conditions.

General purpose for all materials.

MT11 Ultra-fine sub-micron grade with advanced PVD triple coating.

Cutting Feed inch/tooth

ISO Cutting Diameter = D

Standard Materials Speed

ft/min Ø.04 Ø.06 Ø.08 Ø.12 Ø.16 Ø.20 Ø.24 Ø.28 Ø.31 Ø.35 Ø.39 Ø.47 Ø.55 Ø.63

Low and Medium Carbon Steels 200-390 .0016 .0020 .0020 .0028 .0035 .0043 .0051 .0055 .0059 .0063 .0063 .0067 .0071 .0071

<0.55%C

P High Carbon Steels ≥0.55%C 200-300 .0012 .0016 .0020 .0024 .0031 .0035 .0039 .0047 .0051 .0055 .0055 .0063 .0067 .0071

Alloy Steels, Treated Steels 160-260 .0012 .0016 .0016 .0020 .0020 .0024 .0028 .0028 .0031 .0035 .0039 .0047 .0051 .0055

Stainless Steels - Free Cutting 230-330 .0008 .0012 .0012 .0016 .0020 .0024 .0024 .0028 .0031 .0035 .0039 .0043 .0047 .0051

M Stainless Steels - Austenitic 200-300 .0008 .0012 .0012 .0016 .0020 .0024 .0024 .0028 .0031 .0035 .0039 .0043 .0047 .0051

Cast Steels 230-300 .0012 .0016 .0016 .0020 .0020 .0024 .0028 .0028 .0031 .0035 .0039 .0047 .0051 .0055

K Cast Iron 130-260 .0016 .0020 .0020 .0028 .0035 .0043 .0051 .0055 .0059 .0063 .0063 .0067 .0071 .0071

Aluminum ≤12%Si, Copper 330-660 .0016 .0020 .0020 .0028 .0035 .0043 .0051 .0055 .0059 .0063 .0063 .0067 .0071 .0071

Aluminum >12% Si 200-460 .0012 .0012 .0012 .0016 .0020 .0024 .0024 .0028 .0031 .0035 .0039 .0043 .0051 .0054

N

Synthetics, Duroplastics, 160-660 .0035 .0039 .0043 .0047 .0055 .0063 .0071 .0075 .0075 .0075 .0075 .0075 .0079 .0079

Thermoplastics

S Nickel Alloys and Titanium Alloys 70-130 .0012 .0012 .0012 .0016 .0016 .0020 .0024 .0024 .0024 .0028 .0028 .0028 .0031 .0031

start center arc thread arc end

point location entrance milling exit point

Mini Mill-Thread

vs. Taps

Features Mini Mill-Thread Taps

Thread surface quality High Medium

Thread geometry Very accurate Medium

Thread tolerances 4H, 5H, 6H with std cutter 6H with standard tap, 4H with specific tap

Machining time Same as tap or shorter Short

Tool breakage Almost not possible Could happen often

Machining load Very low High

Range of thread diameters Wide range of diameters Specific tap for each diameter

Right/Left hand threading Same cutter Specific tap for each

Geometric shape Full profile Partial profile

8 304