Page 30 - Carmex - Diamond Tools

P. 30

®

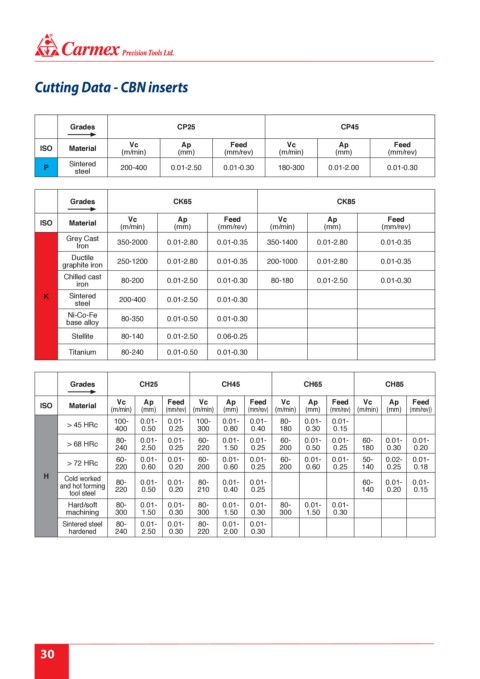

Cutting Data - CBN inserts

Grades CP25 CP45

Vc Ap Feed Vc Ap Feed

ISO Material

(m/min) (mm) (mm/rev) (m/min) (mm) (mm/rev)

Sintered

P 200-400 0.01-2.50 0.01-0.30 180-300 0.01-2.00 0.01-0.30

steel

Grades CK65 CK85

Vc Ap Feed Vc Ap Feed

ISO Material

(m/min) (mm) (mm/rev) (m/min) (mm) (mm/rev)

Grey Cast 350-2000 0.01-2.80 0.01-0.35 350-1400 0.01-2.80 0.01-0.35

Iron

Ductile

graphite iron 250-1200 0.01-2.80 0.01-0.35 200-1000 0.01-2.80 0.01-0.35

Chilled cast

iron 80-200 0.01-2.50 0.01-0.30 80-180 0.01-2.50 0.01-0.30

K Sintered 200-400 0.01-2.50 0.01-0.30

steel

Ni-Co-Fe 80-350 0.01-0.50 0.01-0.30

base alloy

Stellite 80-140 0.01-2.50 0.06-0.25

Titanium 80-240 0.01-0.50 0.01-0.30

Grades CH25 CH45 CH65 CH85

Vc Ap Feed Vc Ap Feed Vc Ap Feed Vc Ap Feed

ISO Material

(m/min) (mm) (mm/rev) (m/min) (mm) (mm/rev) (m/min) (mm) (mm/rev) (m/min) (mm) (mm/rev))

100- 0.01- 0.01- 100- 0.01- 0.01- 80- 0.01- 0.01-

> 45 HRc

400 0.50 0.25 300 0.80 0.40 180 0.30 0.15

80- 0.01- 0.01- 60- 0.01- 0.01- 60- 0.01- 0.01- 60- 0.01- 0.01-

> 68 HRc

240 2.50 0.25 220 1.50 0.25 200 0.50 0.25 180 0.30 0.20

60- 0.01- 0.01- 60- 0.01- 0.01- 60- 0.01- 0.01- 50- 0.02- 0.01-

> 72 HRc

220 0.60 0.20 200 0.60 0.25 200 0.60 0.25 140 0.25 0.18

H Cold worked

80-

60-

80-

and hot forming 220 0.01- 0.01- 210 0.01- 0.01- 140 0.01- 0.01-

0.20

0.50

0.20

0.25

0.40

0.15

tool steel

Hard/soft 80- 0.01- 0.01- 80- 0.01- 0.01- 80- 0.01- 0.01-

machining 300 1.50 0.30 300 1.50 0.30 300 1.50 0.30

Sintered steel 80- 0.01- 0.01- 80- 0.01- 0.01-

hardened 240 2.50 0.30 220 2.00 0.30

30