Page 7 - Carmex - SuperCut Solid Carbide MSD Drills Metric

P. 7

®

SuperCut Solid Carbide MSD Drills

Drill penetration

The surface should be cleanly faced (especially from a nib after

parting off operation) and normal to drill axis.

Boring operation (enlarging of existing hole) can cause chip

forming and evacuation problems, such operation is not

recommended. Pre-hole is not required for short drills up to 5XD,

center drilling preparation is not allowed.

Drill exit

Avoid drill exit on significant slope surfaces because a breakage

danger due to unequal side forces.

In case it can’t be avoided, please reduce feed at the exit.

Cross holes

Crossing existing holes is challenge for the drilling

operation. In case you can’t avoid that please

reduce feed at the crossing stage.

Pecking cycle

Generally, in case of optimal conditions, pecking cycle is not required,

but if a chip evacuation problem occurs, the pecking cycle can be applied.

Using of pecking cycle can reduce drill tool life.

General recommendation

Choose machine with the best stability and high RPM ability for small diameter drills.

Horizontal spindle is preferrable due to better chip evacuation.

Provide suitable coolant supply.

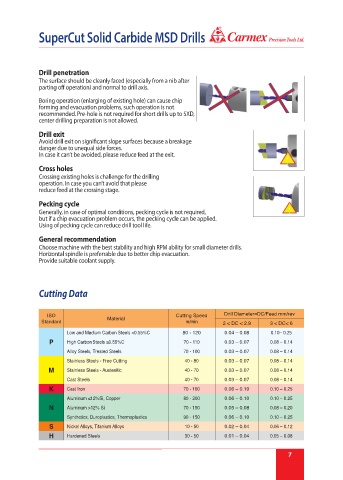

Cutting Data

ISO Cutting Speed Drill Diameter=DC/Feed mm/rev

Material

Standard m/min 2 < DC < 2.9 3 < DC< 6

Low and Medium Carbon Steels <0.55%C 80 - 120 0.04 – 0.08 0.10– 0.25

P High Carbon Steels ≥0.55%C 70 - 110 0.03 – 0.07 0.08 – 0.14

Alloy Steels, Treated Steels 70 - 100 0.03 – 0.07 0.08 – 0.14

Stainless Steels - Free Cutting 40 - 80 0.03 – 0.07 0.08 – 0.14

M Stainless Steels - Austenitic 40 - 70 0.03 – 0.07 0.08 – 0.14

Cast Steels 40 - 70 0.03 – 0.07 0.08 – 0.14

K Cast Iron 70 - 160 0.06 – 0.10 0.10 – 0.25

Aluminum ≤12%Si, Copper 80 - 200 0.06 – 0.10 0.10 – 0.25

N Aluminum >12% Si 70 - 150 0.05 – 0.08 0.08 – 0.20

Synthetics, Duroplastics, Thermoplastics 90 - 150 0.06 – 0.10 0.10 – 0.25

S Nickel Alloys, Titanium Alloys 10 - 50 0.02 – 0.04 0.06 – 0.12

H Hardened Steels 30 - 50 0.01 – 0.04 0.05 – 0.08

7