Page 386 - Carmex - Inch Catalog 2022

P. 386

®

Mill-Thread Technical Section

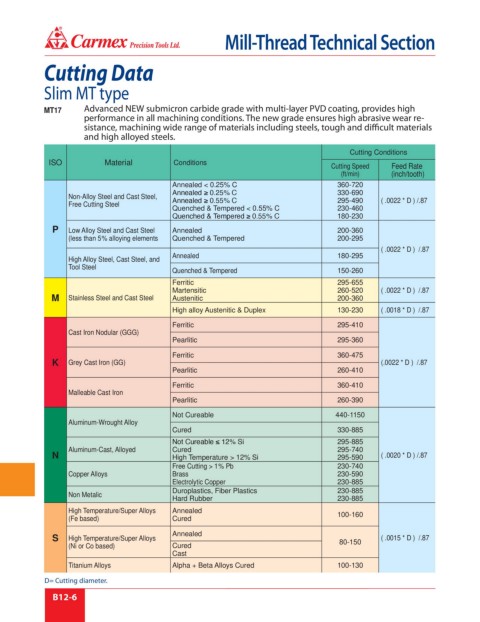

Cutting Data

Slim MT type

Advanced NEW submicron carbide grade with multi-layer PVD coating, provides high

MT17

performance in all machining conditions. The new grade ensures high abrasive wear re-

sistance, machining wide range of materials including steels, tough and difficult materials

and high alloyed steels.

Cutting Conditions

ISO Material Conditions

Cutting Speed Feed Rate

(ft/min) (inch/tooth)

Annealed < 0.25% C 360-720

Annealed ≥ 0.25% C 330-690

Non-Alloy Steel and Cast Steel, Annealed ≥ 0.55% C 295-490 ( .0022 * D ) /.87

Free Cutting Steel

Quenched & Tempered < 0.55% C 230-460

Quenched & Tempered ≥ 0.55% C 180-230

P Low Alloy Steel and Cast Steel Annealed 200-360

(less than 5 % alloying elements Quenched & Tempered 200-295

( .0022 * D ) /.87

Annealed 180-295

High Alloy Steel, Cast Steel, and

Tool Steel

Quenched & Tempered 150-260

Ferritic 295-655

Martensitic 260-520 ( .0022 * D ) /.87

M Stainless Steel and Cast Steel Austenitic 200-360

High alloy Austenitic & Duplex 130-230 ( .0018 * D ) /.87

Ferritic 295-410

Cast Iron Nodular (GGG)

Pearlitic 295-360

Ferritic 360-475

K Grey Cast Iron (GG) (.0022 * D ) /.87

Pearlitic 260-410

Ferritic 360-410

Malleable Cast Iron

Pearlitic 260-390

Not Cureable 440-1150

Aluminum-Wrought Alloy

Cured 330-885

Not Cureable ≤ 12% Si 295-885

Aluminum-Cast, Alloyed Cured 295-740

N High Temperature > 12% Si 295-590 ( .0020 * D ) /.87

Free Cutting > 1 % Pb 230-740

Copper Alloys Brass 230-590

Electrolytic Copper 230-885

Duroplastics, Fiber Plastics 230-885

Non Metalic

Hard Rubber 230-885

High Temperature/Super Alloys Annealed 100-160

(Fe based) Cured

Annealed

S High Temperature/Super Alloys ( .0015 * D ) /.87

(Ni or Co based) Cured 80-150

Cast

Titanium Alloys Alpha + Beta Alloys Cured 100-130

D= Cutting diameter.

B12-6